|

5

|

|

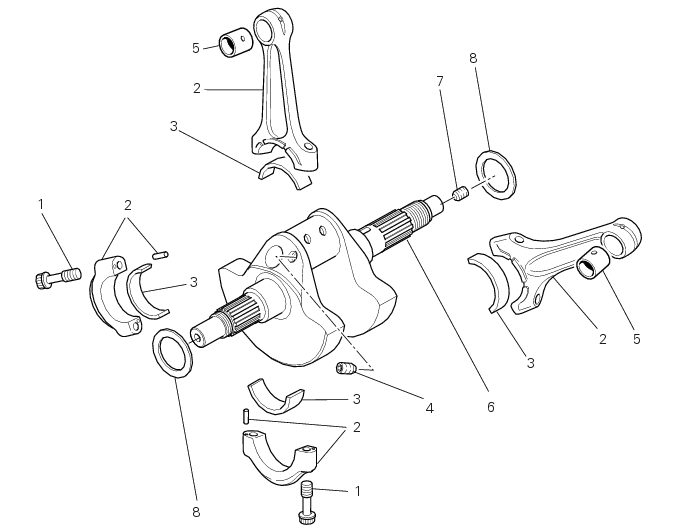

Remove the alternator-side crankcase cover and the alternator assembly

|

|

|

2

|

now carry out a second tightening stage applying a torque of 35 Nm on each screw;

|

|

3

|

now tighten each screw, reading the angle of rotation, to 70 Nm, checking that the final angle is between 55° and 75°.

|

|

Refit the alternator-side crankcase cover and alternator assembly

|

|