|

6.1 -

|

|

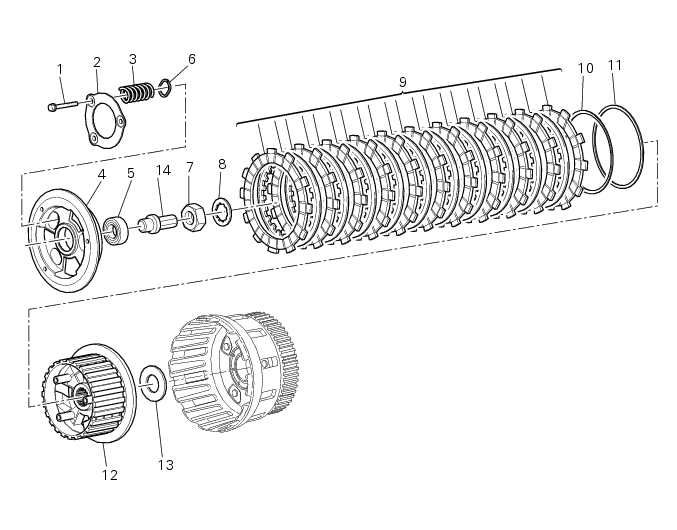

1

|

|

2

|

|

5

|

|

6

|

|

7

|

|

11

|

|

13

|

|

-

|

one driven disc (H), 2 mm thick;

|