|

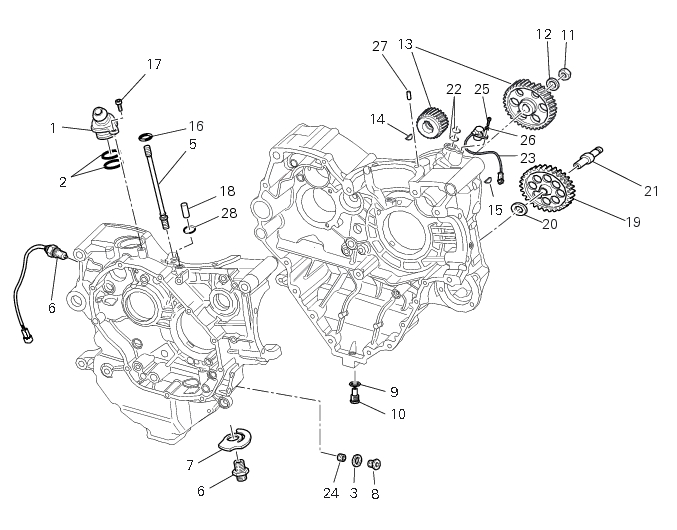

2

|

|

6

|

|

8

|

|

9

|

|

11

|

|

12

|

|

14

|

|

15

|

|

16

|

|

17

|

|

20

|

|

21

|

|

22

|

|

24

|

|

25

|

|

26

|

|

28

|

|

Remove the alternator-side crankcase cover and the alternator assembly

|

|

|

Refit the alternator-side crankcase cover and alternator assembly

|

|

|

Remove the alternator-side crankcase cover and flywheel/alternator assembly

|

|

Refit the flywheel/alternator assembly. and alternator side crankcase cover

|

|

|

Remove the alternator-side crankcase cover and flywheel/alternator assembly

|

|

Refit the flywheel/alternator assembly. and alternator side crankcase cover

|

|