|

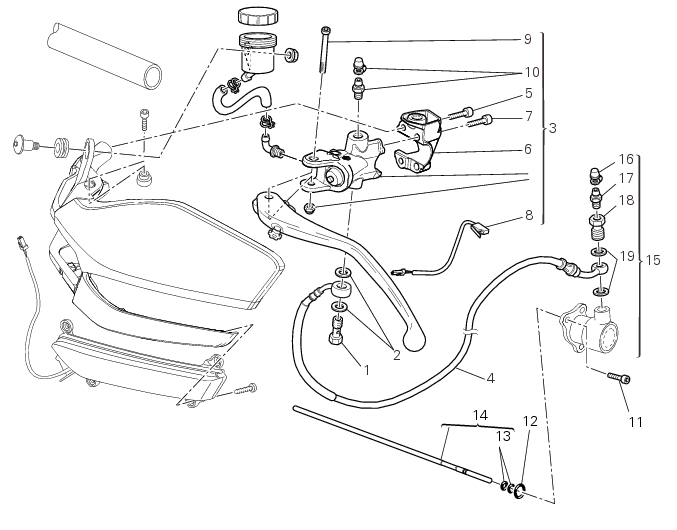

5

|

|

7

|

|

9

|

|

10

|

|

11

|

|

12

|

|

13

|

|

16

|

|

17

|